HAZWOPER Respiratory Protection Factors

HAZWOPER Respiratory Protection Factors

OSHA guidelines require employers to have a respirator protection program in place that outlines and defines the way respirators will be used, stored, inspected, tested, and cleaned. Part of this protection program involves the HAZWOPER Respirator Protection Factor.

About HAZWOPER Respirator Protection Factors

The Assigned Protection Factor (APF) measures the level of protection that a respirator can provide the user. The assigned number represents the relative difference in concentrations of substances both inside and outside the respirator’s facepiece.

For example, the protection factor for a full facepiece air-purifying respirator is 50. That means the user of this respirator can withstand a concentration of chemicals that is 50 times greater than the appropriate limits.

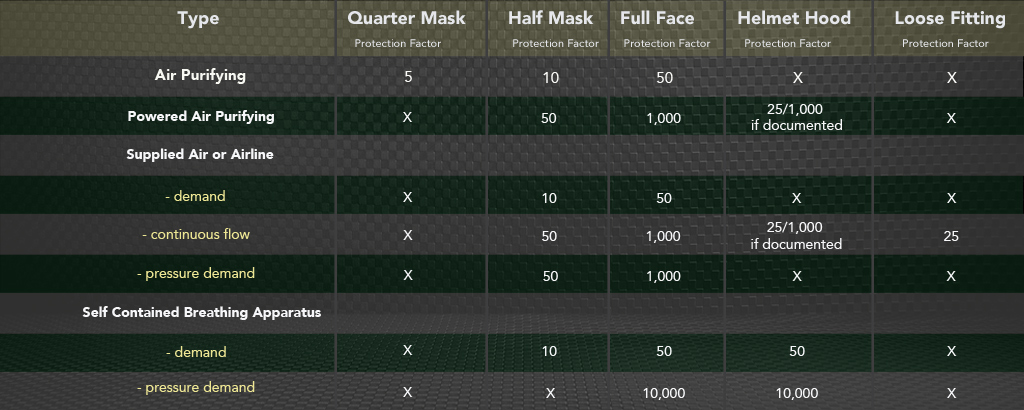

The table below illustrates the protection factors of various types of respirators.

Calculating Usage Limits

Protection factors are determined experimentally by measuring the facepiece seal and exhalation valve leakage.

To determine when and where a particular respirator may be used, multiply the protection factor of the respirator by the chemical’s OSHA Permissible Exposure Limit (PEL), which is also referred to as the Threshold Limit Value (TLV). This will determine the Maximum Value Limit, which is the highest concentration of chemicals for which the respirator may be used.

If the chemical concentration of the atmosphere is more than the Maximum Value Limit, a respirator with a higher protection factor must be used.

Other Factors in Respirator Selection

In addition to the protection factor, there are other key variables in selecting a respirator.

One of those factors is the service limit or life limit of the canister. Once this limit has been reached, the canister can no longer provide sufficient protection. The service limit is usually written on the side of the canister or may otherwise be obtained by contacting the manufacturer.

Other factors to consider when choosing a respirator include the type of airflow (positive or negative airflow) and the type of facepiece.

Respiratory selection should always be left to a qualified person and in accordance with OSHA’s Respiratory Protection standard 29CFR 1910.134: https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.134

Learn More About Respirator Selection

Learn more about protection factors and other variables related to respirator selection by enrolling in our Personal Protective Equipment (PPE) course. Or if you aren’t sure which course is appropriate for yourself or your employees, use our handy guide to decide.

You may register yourself as an individual or all of your employees as a group. View a demonstration of our PPE course and enroll today.