The RCRA TSD Operations refresher course is designed for individuals working at a RCRA Treatment Storage and Disposal Facility (TSDF). OSHA regulations require annual training for anyone certified to respond to incidental releases of hazardous materials, and the EPA requires refresher training for generators of RCRA hazardous waste.

This training is to recertify individuals who will be engaged in Hazardous Waste Operations and Emergency Response (HAZWOPER) work at Treatment, Storage, and Disposal (TSD) facilities in compliance with the Occupational Safety and Health Administration (OSHA) regulation 29 CFR 1910.120.

Note that this course satisfies a different set of regulatory requirements than our RCRA Hazardous Waste Generator course. The U.S. EPA requires training for generators of RCRA hazardous waste, and the hazardous waste generator course is vastly different and does not include certification to respond to releases of hazardous waste to the environment.

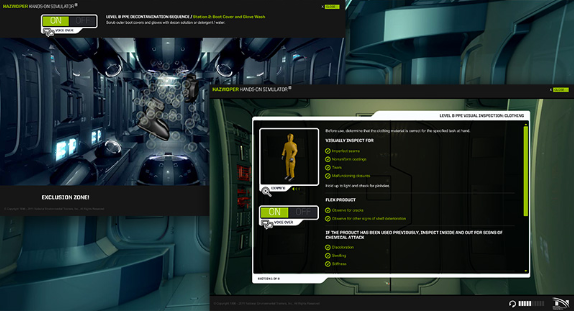

This HAZWOPER refresher course is designed for you to complete on your own time and at your own pace. Train on our HAZWOPER Hands-on Simulator®, the only HAZWOPER training module accepted by OSHA. Start and stop whenever you wish and all of your progress will be saved where you left off. And HAZWOPER On Mobile allows you to work from any device.

Download your e-certificate immediately upon completing the course.

The HAZWOPER course counts as continuing education units (CEUs). This course is accepted for 1.34 Industrial Hygiene CM Points by the American Board of Industrial Hygiene (ABIH) and .8 Continuance of Certification (COC) points from the Board of Certified Safety Professionals (BCSP).

U.S.-based support is available throughout the course

This course includes the OSHA-accepted HAZWOPER Hands-On Simulator®

Learn more about the hands on simulator“Our group really enjoyed the course — very informative and professionally developed.” — Pete Knight, Navy Public Works

The HAZWOPER 8-Hour Annual Refresher - RCRA TSD Operations course consists of 14 full-length videos featuring award-winning content and over 75 interactive animations. The course includes self-grading quizzes and a final exam, and an OSHA Study Timer tracks your progress every step of the way.

This 8-hour HAZWOPER course has been awarded 1.34 Industrial Hygiene CM Points by the American Board of Industrial Hygiene (ABIH) — approval number 13334. This course is eligible for .8 Continuance of Certification (COC) points from the Board of Certified Safety Professionals (BCSP).

The HAZWOPER 8-Hour Annual Refresher course is made up of over 60 modules and teaches:

The objective of this HAZWOPER refresher course is to provide refresher training and recertification.

OSHA-approved Plan States must maintain standards that are at least as stringent as the Federal HAZWOPER training regimen and may have additional training requirements of their own.

While this training course is very comprehensive, we highly recommend that additional site-specific training be taken for certain hazardous materials that may be encountered at different sites. OSHA regulations require site-specific training as opposed to attending a generic public seminar class for hands on training with PPE. This means students will train on the actual equipment they will be using as employees and not just a generic piece of equipment.