The 24-Hour HAZWOPER — RCRA TSD Operations course is designed for any individuals who will be working in an area defined as a Resource Conservation and Recovery Act (RCRA) Treatment Storage or Disposal (TSD) facility.

This course is intended for RCRA TSD site personnel, e.g., supervisors, environmental professionals, workers, decon personnel, etc. The initial training for new employees exposed to health hazards or hazardous substances at TSD facilities must be 24 hours. This includes personnel at facilities that have the potential for an emergency to occur due to an uncontrolled release of hazardous substances or hazardous raw materials. Any employer with a hazardous waste storage area is required to provide training under 29 CFR 1910.120 (p)(8) or (q).

Initial training requires 24 hours of coursework while refresher training requires 8 hours annually. OSHA requires the 24-hour course will take a minimum of 24 hours of actual study time. Anything less will not comply with the OSHA standard. Our course allows you to login and logout at any time increment in order to fit your schedule. Training must be incorporated into the employer's safety and health program.

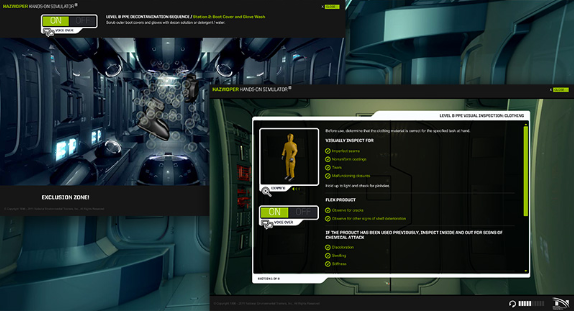

Train on the HAZWOPER Hands-on Simulator, the only OSHA-approved HAZWOPER trainer. You can also complete your HAZWOPER training online using any device with HAZWOPER On Mobile.

Work at your own convenience and your progress will be saved right where you left off.

Download an e-certificate immediately upon course completion.

U.S.-based support is available throughout the course and a study timer indicates how much time you have accrued and how much you have left.

The 24-hour HAZWOPER course counts as continuing education units (CEUs). This course is accepted for 4.01 Industrial Hygiene CM Points by the American Board of Industrial Hygiene (ABIH) and 2.4 Continuance of Certification (COC) points from the Board of Certified Safety Professionals (BCSP).

This course includes the OSHA-accepted HAZWOPER Hands-On Simulator®

Learn more about the hands on simulatorThe 24-Hour HAZWOPER — RCRA TSD Operations course is comprised of 15 videos, over 80 interactive modules, and professional voiceovers of award-winning content. You'll complete the course through a series of self-grading quizzes and a final exam.

All completed hours count as CEUs (Continuing Education Units).

You have one full year to complete the course upon time of registration. This course may be taken on an individual basis or in group settings.

This HAZWOPER certification course is made up of 86 modules and upon completion of training, you will have a thorough understanding of:

There are no prerequisites for the 24-Hour HAZWOPER — RCRA TSD Operations course.

Did you know that there are at least 3 different 24-hour HAZWOPER courses? OSHA requires that employers adequately train their employees for any job. Please be sure you get the right HAZWOPER Training for the right job.

The RCRA corrective action process consists of three primary activities: characterizing the release, selecting a remedy from identified alternatives, and implementing the selected remedy until the desired remediation goals are achieved. To design a process capable of collecting the information necessary to achieve these primary objectives, the HAZWOPER employer relies not only on this guidance document but others prepared by the EPA which describe all aspects of the corrective action process.

Plan States (approved by U.S. OSHA) must have standards at least as stringent as the Federal HAZWOPER training requirements. These Plan States may have additional training requirements.