The HAZWOPER First Responder Operations course is required training for individuals preparing to serve in a first responder role on a Hazardous Waste Operations and Emergency Response (HAZWOPER) team.

HAZWOPER first responders respond to the release or potential release of hazardous materials for the purpose of containing the release and preventing exposures to persons, property, and the environment. They are trained to respond in a defensive fashion without actually trying to stop the release Their primary focus is to contain the release from a safe distance, keep it from spreading and to prevent exposures.

This course satisfies the annual OSHA training requirements of 29 CFR1910.120 for First Responder Operations.

The HAZWOPER First Responder Operations course is designed to allow students to complete their training online at their own convenience. The class is self-paced, meaning you can stop at any time and pick up where you left off later. HAZWOPER On Mobile also allows you to work from any device.

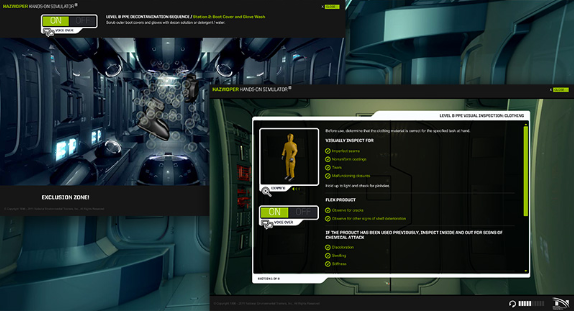

Train on the HAZWOPER Hands-on Simulator®, the only OSHA-accepted HAZWOPER trainer. You can download your certificate immediately upon finishing the course.

The HAZWOPER course counts as continuing education units (CEUs). This course is accepted for 1.34 Industrial Hygiene CM Points by the American Board of Industrial Hygiene (ABIH) and .8 Continuance of Certification (COC) points from the Board of Certified Safety Professionals (BCSP).

Group discounts are available for 2 or more people.

This course includes the OSHA-accepted HAZWOPER Hands-On Simulator®

Learn more about the hands on simulator“We enjoyed the content and delivery of your training.” S. Maide, U.S. EPA

The HAZWOPER First Responder Operations course features 14 full-length videos, self-grading quizzes, and a final exam. The award-winning training content includes audio narration and more than 35 interactive animations.

U.S.-based support is available to you throughout the course and an OSHA Study Timer tracks your accrued time and saves your work as you log in and out. All completed hours count as Continuing Education Units (CEUs).

The course is self-paced and can be completed online, at any time.

The HAZWOPER First Responder Operations course is designed to prepare students to be the first on the scene of a hazardous materials incident. Upon completion of the course, students will have a thorough understanding of:

This HAZWOPER First Responder course has been awarded 1.34 Industrial Hygiene CM Points by the American Board of Industrial Hygiene (ABIH) — approval number 13334. This course is eligible for .8 Continuance of Certification (COC) points from the Board of Certified Safety Professionals (BCSP).

This course has no prerequisites.

Plan States approved by OSHA must have training requirements that at minimum meet those of Federal HAZWOPER Training and may have additional training requirements of their own.

While this training course is comprehensive, additional site-specific training must be taken for certain hazardous materials that may be encountered at different sites.