You will need the National Environmental Trainers' (NET) 8-hour HAZWOPER Supervisor Training if you'll have a supervisory role at a HAZWOPER site, according to OSHA requirements.

A supervisor is responsible for planning, organizing, and directing employees. This NET online course is specially designed for foremen, site safety officers, and project managers. You must have already completed the 40- or 24-Hour HAZWOPER before beginning this training.

In addition to the HAZMAT and HAZWOPER certification, annual refresher courses are required to maintain HAZWOPER supervisor certification.

Take the web's most trusted, authoritative, and popular 40-hour HAZWOPER Training online course featuring the HAZWOPER Hands-on Simulator®.

HAZWOPER On Mobile allows you to take the course on any computer or mobile device.

Your study sessions will be tracked so you can log in and out any time, beginning where you left off in both time and content.

You'll know your accrued study time throughout the training through a visible study timer. Support is available throughout the course.

The 8-hour HAZWOPER course counts as continuing education units (CEUs). This course is accepted for 1.34 Industrial Hygiene CM Points by the American Board of Industrial Hygiene (ABIH) and .8 Continuance of Certification (COC) points from the Board of Certified Safety Professionals (BCSP).

As soon as you complete the online certification training, you may download your certificate.

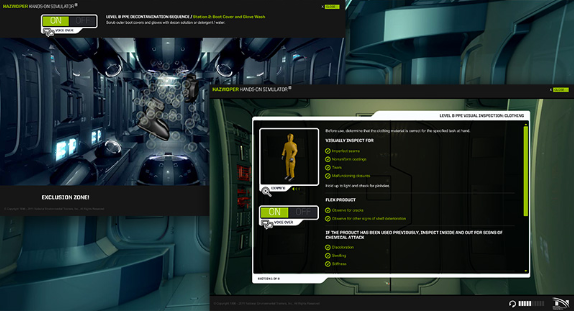

This course includes the OSHA-accepted HAZWOPER Hands-On Simulator®

Learn more about the hands on simulatorNET's online 8-hour Supervisor Training features the OSHA-accepted HAZWOPER Hands-on Simulator® and award-winning content including 14 professional videos and 60 interactive modules.

While you study for HAZWOPER certification or CEUs, you will have online support and the study time will track your progress. After registering, you'll have a year to complete the course or access it for reference.

Upon completion of the training, you will be able to:

Yes, the HAZWOPER 8-hour Supervisor Training refresher serves as a refresher for the regular 8-hour HAZWOPER refresher.

OSHA-approved Plan States must have standards at least as stringent as the Federal HAZWOPER training requirements. They may also have additional training requirements.