The HAZMAT Specialist course is required for individuals who plan to work as emergency responders with a HAZMAT Specialist designation. This includes fire, rescue, Emergency Medical Services (EMS), general industry, and other professionals who may respond to and mitigate incidents involving hazardous materials.

HAZMAT Specialists respond to releases or potential releases of hazardous materials for the purpose of controlling the release. They are more aggressive than first responders at the operations level in that they will approach the point of release to plug, patch, or otherwise stop the release of a hazardous materials substance.

They are expected to use specialized chemical protective clothing and specialized control equipment. They are also specialists within certain designations that perform operations to contain, confine, or mitigate hazardous substances releases. Our HAZMAT Specialist training prepares responders to use specialized chemical protective clothing and control equipment to patch, plug, and otherwise mitigate the release or spread of hazardous material.

See why so many professionals choose National Environmental Trainers for their HAZMAT certification.

Start and stop the course as often as you wish and your progress will be saved where you left off.

Utilize HAZWOPER On Mobile to take the course on any device from any location.

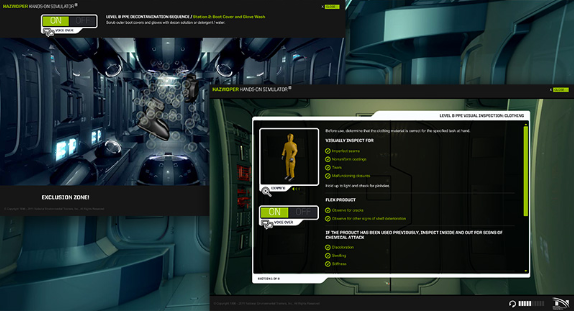

Train on the HAZWOPER Hands-on Simulator®, the only OSHA-accepted HAZWOPER trainer.

Immediately download an e-certificate upon completion of the course.

The HAZMAT Specialist course counts as continuing education units (CEUs). This course is accepted for 4.01 Industrial Hygiene CM Points by the American Board of Industrial Hygiene (ABIH) and 2.4 Continuance of Certification (COC) points from the Board of Certified Safety Professionals (BCSP).

Group discounts are available to parties of two or more people.

This course includes the OSHA-accepted HAZWOPER Hands-On Simulator®

Learn more about the hands on simulator“Your HAZMAT Specialist training was really good.” — Steve Schmidt, Georgia Power

The HAZMAT Specialist course is made up of 14 videos and over 80 interactive modules of award-winning contents.

You'll learn via self-grading quizzes and a final exam while support is made available throughout the course. A study timer keeps you updated on your completed hours, which all count as CEUs.

This HAZMAT Specialist training has been awarded 4.01 Industrial Hygiene CM Points by the American Board of Industrial Hygiene (ABIH) — approval number 13334. This course is eligible for 2.40 Continuance of Certification (COC) points from the Board of Certified Safety Professionals (BCSP).

A minimum of 24 hours of study time is required to successfully complete HAZMAT Specialist training and earn a certificate. Upon completion of the course, students will be ready to function within an assigned role within the Incident Command System and will be prepared to implement the employer's emergency response plan.

In addition to acquiring an understanding of basic chemical and toxicological terminology and behavior along with procedures for termination and decontamination, students will complete the course with a thorough understanding of:

Our HAZMAT Specialist course allows you to earn your HAZMAT certification online. A prerequisite of 24 hours of HAZMAT Technician level training or equivalent is needed prior to completing the HAZMAT Specialist course.

The HAZMAT Specialist training is taken online. As with any training (classroom or online) the employer is required by regulations to train the employee(s) on performance-based standards for any applicable equipment. This is a site-specific requirement and typically cannot be achieved in a regular public seminar or open enrollment classes where training on a respirator(s) or PPE in general does not meet the site-specific regulatory requirement. Generic hands-on training on PPE and equipment does not fully meet the OSHA regulations.

Plan States (approved by U.S. OSHA) must have standards at least as stringent as the Federal HAZWOPER training requirements. These Plan States may have additional training requirements.

Did you know there are five 24-Hour HAZWOPER courses required by the OSHA standard 29 CFR 1910.120? Each of these courses is very different in who they apply to and the topics covered during the training. Learn which course is right for you.