The HAZWOPER 8-hour Incident Command course is designed to train individuals to assume Incident Command roles within a HAZMAT team in compliance with OSHA 29 CFR 1910.120(q) regulations.

This course is for anyone who may assume an ICS Command or General Staff role on a HAZMAT incident. In compliance with OSHA 29 CFR 1910.120(q) regulations, this annual training is required for individuals having a role with Hazardous Waste Operations and Emergency Response.

This course complies with OSHA regulations and must be provided for personnel who direct or command incident command operations. OSHA-approved Plan States must have standards at least as stringent as the Federal HAZWOPER training requirements and may have additional requirements of their own.

The HAZWOPER 8-hour Incident Command course allows students to complete their HAZWOPER training online at their own convenience. Start and stop as needed and have all of your progress saved where you left off. And HAZWOPER On Mobile allows you to work from any device.

Download your HAZWOPER certification as soon as you complete the course.

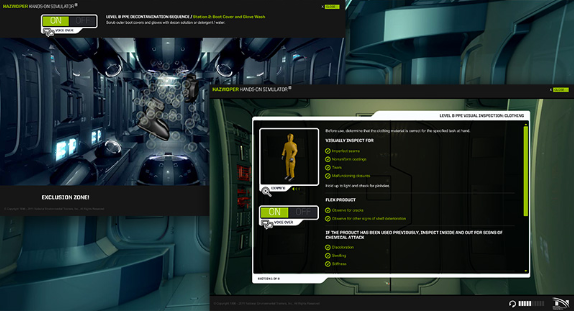

Train on the OSHA-accepted HAZWOPER Hands-on Simulator®.

The 8-hour HAZWOPER course counts as continuing education units (CEUs). This course is accepted for 1.34 Industrial Hygiene CM Points by the American Board of Industrial Hygiene (ABIH) and .8 Continuance of Certification (COC) points from the Board of Certified Safety Professionals (BCSP)

This course includes the OSHA-accepted HAZWOPER Hands-On Simulator®

Learn more about the hands on simulator“We enjoyed the content and delivery of your training.” S. Maide, U.S. EPA

The HAZWOPER 8-hour Incident Command course is made up of 14 videos, self-graded quizzes and a final exam. Award-winning content features over 50 interactive modules while a study timer tracks your progress every step of the way.

U.S.-based support is available throughout the course and all completed hours count as Continuing Education Units (CEUs).

This course has been awarded 1.34 Industrial Hygiene CM Points by the American Board of Industrial Hygiene (ABIH) — approval number 13334. This course is eligible for .80 Continuance of Certification (COC) points from the Board of Certified Safety Professionals (BCSP).

This HAZWOPER training course is designed to equip students with the ability to understand and execute an emergency response plan and assume the responsibility of an Incident Command role within a hazardous materials team.

Topics covered in the course include:

This course complies with OSHA regulations and can be taken online. The course consists of modules with the use of multimedia components for an engaging experience. This training must be provided for personnel who direct or command incident response operations.

The HAZMAT First Responder Operations course is a required prerequisite of the HAZWOPER 8-hour Incident Command course.