If you are an engineer or scientist who needs the HAZWOPER 8-Hour Annual Refresher course, National Environmental Trainers (NET) offers a course specifically for you.

This course meets OSHA requirements for annual recertification of the 24-hour HAZWOPER or 40-hour HAZWOPER general site worker courses. If a substantial amount of time has passed since your initial course or last refresher training, you may need to repeat the 24- or 40-hour HAZWOPER course.

NET's online course complies with OSHA 29 CFR 1910.120 paragraph (e) regulations. This engaging, interactive course is self-paced.

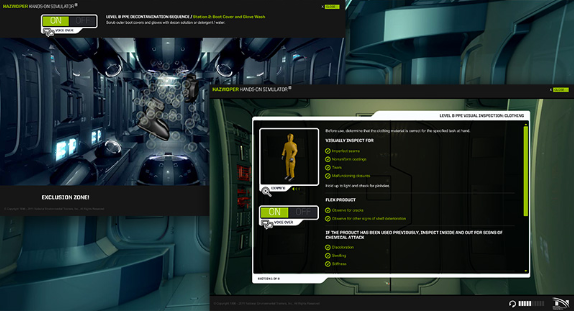

National Environmental Trainers (NET) offers the added assurance that our HAZWOPER refresher course complies with the OSHA regulations. We have an interpretation letter from the U.S. OSHA Directorate of Enforcement Programs in Washington D.C., accepting our HAZWOPER Hands-on Simulator®. No other online company has such a letter from OSHA.

Take the course on any computer or mobile device at any time.

Track your study time and place in the course, allowing you to log in and out at your convenience.

See your accrued time as you study through a visible course timer. You will have to accumulate a minimum of 8 hours within the course.

Self-grading quizzes throughout course prepares you for the final exam.

Customer and instructor support while you take the course.

A downloadable e-certificate is provided when you pass the course.

The 8-hour HAZWOPER course counts as continuing education units (CEUs). This course is accepted for 1.34 Industrial Hygiene CM Points by the American Board of Industrial Hygiene (ABIH) and .8 Continuance of Certification (COC) points from the Board of Certified Safety Professionals (BCSP).

This course includes the OSHA-accepted HAZWOPER Hands-On Simulator®

Learn more about the hands on simulator“The best HAZWOPER Refresher we've ever had” — Robert Scheirer, Ph.D., Northeast Restoration, Inc.

NET HAZWOPER training online has won awards for its content modules which feature over 35 interactive animations, 14 full-length videos, and the HAZWOPER Hands-on Simulator®.

This course includes the topics necessary to help you work safely at your job. It's essential to understand the protective abilities and limitations of equipment to minimize exposure to hazardous substances at places like abandoned hazardous waste sites and Superfund sites. NET allows you to access this course for a year from the time of registration, in case you need to review specifics.

All HAZWOPER-certified individuals are required to take annual refresher training in accordance with OSHA 29 CFR 1910.120 regulations. This specialty refresher course goes above and beyond our standard HAZWOPER 8-Hour Annual Refresher having been designed by engineers and scientists for engineers and scientists. The course includes modules that make use of multimedia components for an engaging experience. This course is to be completed as your annual refresher training after having previously completed the 24- or 40-hour HAZWOPER training.

If you work in an OSHA-approved Plan State, you may need additional site-specific training for certain hazardous materials and environments that you may encounter at your site. This is an employer obligation.

If you have missed a refresher training course because of unavoidable circumstances, you should take the refresher course immediately. You may have to repeat your 24-hour HAZWOPER or 40-hour HAZWOPER training if too much time has passed since your initial course or last refresher. The time frame considered “substantial” will be determined on a case-by-case basis.

HAZWOPER refresher training is required for work at all contaminated sites, including that done by scientists and engineers. These sites are placed on the National Priority List (NPL) by the U.S. Environmental Protection Agency (EPA) and are scheduled for clean-up. The responsible party as identified in the EPA regulations, usually the site owner or past occupant, must cover the clean-up cost.